Available in an assortment of sizes, our tube and pipe range at Ferrocut is manufactured to the relevant Australian Standards. Our inventory includes Square Hollow Sections (SHS), Rectangular Hollow Sections (RHS), Circular Hollow Sections (CHS), Firepipe and Large Structural Pipe.

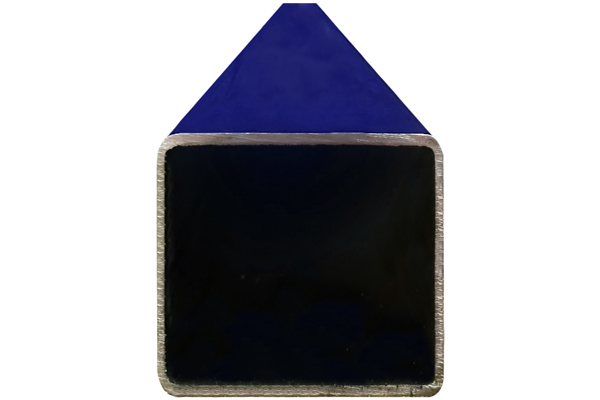

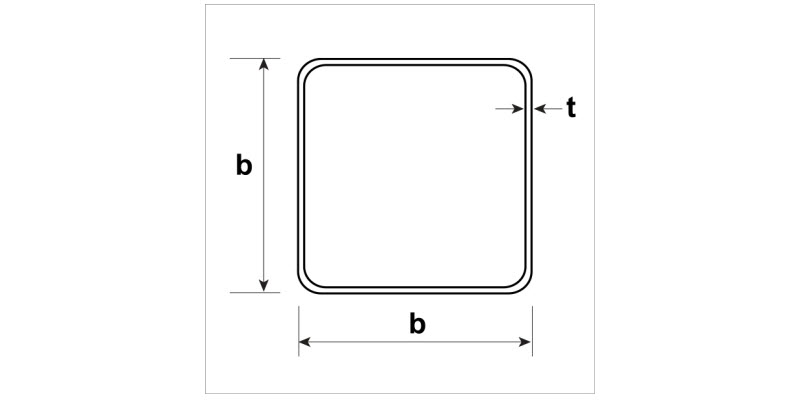

Square Hollow Sections - SHS

Painted Square Hollow Sections (SHS) are high-strength cold-formed hollow steel square sections that are primer painted for protection during storage and handling. SHS is often used when strength and functionality are essential in structural and mechanical applications, more commonly used in the manufacturing of frames, residential projects for gates and posts, as well as other commercial and agricultural purposes. Ferrocut’s SHS products are available in a range of heights and thicknesses and are manufactured in accordance with the requirements of Australian Standard AS/NZS 1163:2009.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 1163:2009 in Grade C350

- Grade C450 and L0 available on request

SIZE (BXB) MM | NOM.THICK (T) MM | NOM.LINEAR MASS KG/M | SURFACE AREA M2/M PER PACK | PAINTED PER PACK | SURFACE FINISH PAINTED | SURFACE FINISH GALVANISED |

6500 MM LENGTHS STANDARD | ||||||

20x20 | 1.6 | 0.87 | 0.0745 | 100 | * | * |

2.0 | 1.05 | 0.0800 | 100 | * | * | |

25x25 | 1.6 | 1.12 | 0.0945 | 100 | * | * |

2.0 | 1.36 | 0.0931 | 100 | * | * | |

2.5 | 1.64 | 0.0914 | 100 | * | * | |

3.0 | 1.89 | 0.0897 | 100 | * | * | |

8000MM LENGTHS STANDARD | ||||||

30x30 | 1.6 | 1.38 | 0.115 | 100 | * | * |

2.0 | 1.68 | 0.113 | 100 | * | * | |

2.5 | 2.03 | 0.111 | 100 | * | * | |

3.0 | 2.36 | 0.110 | 64 | * | * | |

35x35 | 1.6 | 1.63 | 0.135 | 100 | * | * |

2.0 | 1.99 | 0.133 | 100 | * | * | |

2.5 | 2.42 | 0.131 | 64 | * | * | |

3.0 | 2.83 | 0.130 | 64 | * | * | |

40x40 | 1.6 | 1.88 | 0.155 | 81 | * | * |

2.0 | 2.31 | 0.153 | 81 | * | * | |

2.5 | 2.82 | 0.151 | 64 | * | * | |

3.0 | 3.30 | 0.150 | 64 | * | * | |

4.0 | 4.09 | 0.143 | 49 | * | * | |

50x50 | 1.6 | 2.38 | 0.195 | 64 | * | * |

2.0 | 2.93 | 0.193 | 64 | * | * | |

2.5 | 3.60 | 0.191 | 49 | * | * | |

3.0 | 4.25 | 0.190 | 49 | * | * | |

4.0 | 5.35 | 0.183 | 36 | * | * | |

SIZE (BXB) MM | NOM.THICK (T) MM | NOM.LINEAR MASS KG/M | SURFACE AREA M2/M PER PACK | 8M LENGTHS PER PACK | 12M LENGTHS PER PACK | SURFACE FINISH PAINTED | SURFACE FINISH GALVANISED |

50x50 | 5.0 | 6.39 | 0.179 | 30 | - | * | * |

6.0 | 7.32 | 0.174 | 25 | - | OILED | ||

65x65 | 1.6 | 3.13 | 0.255 | 49 | - | * | |

2.0 | 3.88 | 0.253 | 42 | - | * | * | |

2.5 | 4.78 | 0.251 | 42 | - | * | * | |

3.0 | 5.66 | 0.250 | 36 | - | * | * | |

4.0 | 7.23 | 0.243 | 30 | - | * | * | |

5.0 | 8.75 | 0.239 | 25 | - | * | * | |

6.0 | 10.20 | 0.234 | 20 | - | * | ||

75x75 | 2.0 | 4.50 | 0.293 | 36 | - | * | * |

2.5 | 5.56 | 0.291 | 30 | - | * | * | |

3.0 | 6.60 | 0.290 | 30 | 25 | * | * | |

3.5 | 7.53 | 0.285 | 25 | - | * | * | |

4.0 | 8.49 | 0.283 | 25 | 15 | * | * | |

5.0 | 10.30 | 0.279 | 20 | 16 | * | * | |

6.0 | 12.00 | 0.274 | 16 | 12 | * | * | |

89x89 | 2.0 | 5.38 | 0.348 | 20 | - | * | * |

3.5 | 9.07 | 0.341 | 20 | 16 | * | * | |

5.0 | 12.50 | 0.334 | 16 | 12 | * | * | |

6.0 | 14.70 | 0.330 | 12 | 9 | * | * | |

100x100 | 2.0 | 6.07 | 0.393 | 20 | - | * | * |

3.0 | 8.96 | 0.390 | 20 | 16 | * | * | |

4.0 | 11.60 | 0.383 | 16 | 12 | * | * | |

5.0 | 14.20 | 0.379 | 12 | 9 | * | * | |

6.0 | 16.70 | 0.374 | 12 | 9 | * | * | |

9.0 | 23.50 | 0.361 | 9 | 6 | * | ||

125x125 | 4.0 | 14.80 | 0.483 | 12 | 9 | * | * |

5.0 | 18.20 | 0.479 | 12 | 9 | * | * | |

6.0 | 21.40 | 0.474 | 9 | 6 | * | ||

9.0 | 30.60 | 0.461 | 8 | 4 | * | ||

150x150 | 5.0 | 22.10 | 0.579 | 9 | 6 | * | |

6.0 | 26.20 | 0.574 | 6 | 6 | * | ||

9.0 | 37.70 | 0.561 | 6 | 4 | * | ||

200x200 | 5.0 | 29.90 | 0.779 | 6 | 4 | * | |

6.0 | 35.60 | 0.774 | 6 | 4 | * | ||

9.0 | 51.80 | 0.761 | 4 | 2 | * | ||

12.5 | 69.40 | 0.768 | - | 1 | * | ||

16.0 | 85.50 | 0.759 | - | 1 | * | ||

250x250 | 6.0 | 45.00 | 0.974 | 4 | 2 | * | |

9.0 | 65.90 | 0.961 | 2 | 2 | * | ||

12.5 | 89.00 | 0.968 | - | 1 | * | ||

16.0 | 111.00 | 0.959 | - | 1 | * | ||

300x300 | 10.0 | 88.40 | 1.170 | - | 1 | * | |

12.5 | 109.00 | 1.170 | - | 1 | * | ||

16.0 | 136.00 | 1.160 | - | 1 | * | ||

350x350 | 10.0 | 104.00 | 1.370 | - | 1 | * | |

12.5 | 128.00 | 1.370 | - | 1 | * | ||

16.0 | 161.00 | 1.360 | - | 1 | * | ||

400x400 | 10.0 | 120.00 | 1.570 | - | 1 | * | |

12.5 | 148.00 | 1.570 | - | 1 | * | ||

16.0 | 186.00 | 1.560 | - | 1 | * |

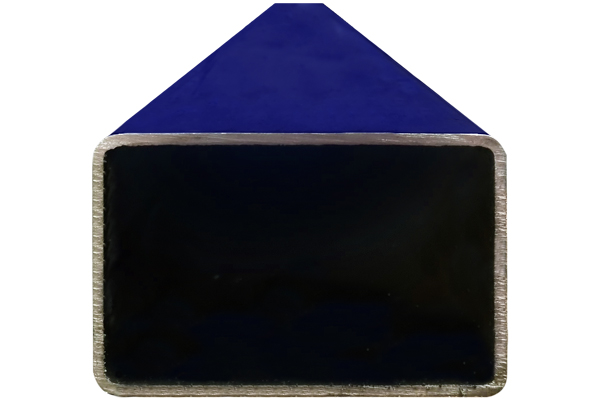

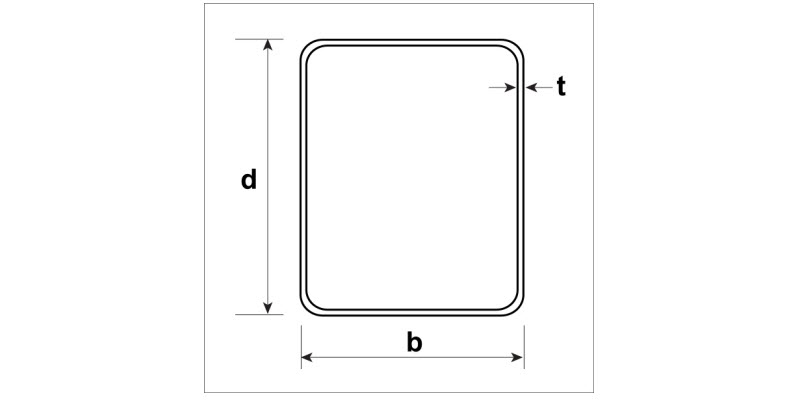

Rectangular Hollow Sections - RHS

Painted Rectangular Hollow Sections (RHS) are high-strength cold-formed hollow steel rectangle sections that are primer painted for protection during storage and handling. RHS is often used when strength and functionality are essential in structural and mechanical applications, and can be used for various applications such as in the manufacturing of frames, residential projects for gates and posts, as well as other commercial and agricultural purposes. Ferrocut’s RHS products are available in a range of heights and thicknesses and are manufactured in accordance with the requirements of Australian Standard AS/NZS 1163:2009.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 1163:2009 in Grade C350

- Grade C450 and L0 available on request

SIZE (BXB) MM | NOM.THICK (T) MM | NOM.LINEAR MASS KG/M | SURFACE AREA M2/M PER PACK | 8M LENGTHS PER PACK | 12M LENGTHS PER PACK | SURFACE FINISH PAINTED | SURFACE FINISH GALVANISED |

50x25 | 1.6 | 1.75 | 0.145 | 96 | - | * | * |

2.0 | 2.15 | 0.143 | 96 | - | * | * | |

2.5 | 2.62 | 0.141 | 72 | - | * | * | |

3.0 | 3.07 | 0.140 | 60 | - | * | * | |

65x35 | 2.0 | 2.93 | 0.193 | 54 | - | * | * |

2.5 | 3.60 | 0.191 | 54 | - | * | * | |

3.0 | 4.25 | 0.190 | 45 | - | * | * | |

4.0 | 5.35 | 0.183 | 35 | - | * | * | |

75x25 | 1.6 | 2.38 | 0.195 | 65 | - | * | * |

2.0 | 2.9 | 0.193 | 65 | - | * | * | |

2.5 | 3.60 | 0.191 | 48 | - | * | * | |

75x50 | 1.6 | 3.01 | 0.245 | 54 | 54 | * | * |

2.0 | 3.72 | 0.243 | 42 | 42 | * | * | |

2.5 | 4.58 | 0.241 | 42 | 24 | * | * | |

3.0 | 5.42 | 0.240 | 35 | - | * | * | |

4.0 | 6.92 | 0.233 | 28 | - | * | * | |

5.0 | 8.35 | 0.229 | 24 | 20 | * | * | |

6.0 | 9.67 | 0.224 | 20 | - | * | * | |

100x50 | 1.6 | 3.64 | 0.295 | 32 | 32 | * | * |

2.0 | 4.50 | 0.293 | 32 | - | * | * | |

2.5 | 5.56 | 0.291 | 32 | 24 | * | * | |

3.0 | 6.60 | 0.290 | 32 | 24 | * | * | |

3.5 | 7.53 | 0.285 | 24 | 18 | * | * | |

4.0 | 8.49 | 0.283 | 24 | 18 | * | * | |

5.0 | 10.30 | 0.279 | 18 | 15 | * | * | |

6.0 | 12.00 | 0.274 | 15 | - | * | * | |

102x76 | 3.5 | 9.07 | 0.341 | 12 | - | * | |

5.0 | 12.50 | 0.335 | 12 | - | * | ||

6.0 | 14.70 | 0.330 | 12 | - | * | ||

125x75 | 2.0 | 6.07 | 0.393 | 24 | - | * | |

2.5 | 7.53 | 0.391 | 20 | 20 | * | ||

3.0 | 8.96 | 0.390 | 20 | 15 | * | * | |

4.0 | 11.60 | 0.383 | 15 | 15 | * | * | |

5.0 | 14.20 | 0.379 | 15 | 12 | * | * | |

6.0 | 16.70 | 0.374 | 12 | 6 | * | * | |

150x50 | 2.0 | 6.07 | 0.393 | 21 | 21 | * | * |

2.5 | 7.53 | 0.391 | 21 | - | * | * | |

3.0 | 8.96 | 0.390 | 21 | 15 | * | * | |

4.0 | 11.60 | 0.383 | 15 | 15 | * | * | |

5.0 | 14.20 | 0.379 | 15 | 9 | * | * | |

6.0 | 16.70 | 0.374 | 15 | 9 | * | * | |

152x76 | 5.0 | 16.50 | 0.435 | 8 | 8 | * | |

6.0 | 19.40 | 0.430 | 8 | - | * | ||

150x100 | 4.0 | 14.80 | 0.483 | 12 | 9 | * | * |

5.0 | 18.20 | 0.479 | 12 | 8 | * | * | |

6.0 | 21.40 | 0.474 | 9 | 6 | * | ||

9.0 | 30.60 | 0.461 | 6 | 4 | * | ||

200x100 | 4.0 | 17.90 | 0.583 | 8 | 6 | * | |

5.0 | 22.10 | 0.579 | 8 | 6 | * | ||

6.0 | 26.20 | 0.574 | 8 | 4 | * | ||

9.0 | 37.70 | 0.561 | 6 | 4 | * | ||

250x150 | 5.0 | 29.90 | 0.779 | 6 | 4 | * | |

6.0 | 35.60 | 0.774 | 6 | 4 | * | ||

9.0 | 51.80 | 0.761 | 4 | 2 | * | ||

12.5 | 69.40 | 0.768 | - | 1 | * | ||

16.0 | 85.50 | 0.759 | - | 1 | * | ||

300x200 | 6.0 | 45.00 | 0.985 | 2 | 1 | * | |

8.0 | 51.10 | 0.979 | 2 | 1 | * | ||

9.0 | 65.90 | 0.976 | - | 2 | * | ||

10.0 | 72.70 | 0.974 | 1 | 1 | * | ||

12.5 | 89.00 | 0.968 | - | 1 | * | ||

16.0 | 111.00 | 0.959 | - | 1 | * | ||

350x250 | 8.0 | 71.58 | 1.077 | - | 1 | * | |

10.0 | 88.40 | 1.071 | - | 1 | * | ||

12.5 | 109.00 | 1.065 | - | 1 | * | ||

16.0 | 136.00 | 1.055 | - | 1 | * | ||

400x200 | 8.0 | 71.60 | 1.180 | - | 2 | * | |

10.0 | 88.40 | 1.170 | - | 1 | * | ||

12.5 | 109.00 | 1.170 | - | 1 | * | ||

16.0 | 136.00 | 1.160 | - | 1 | * | ||

400x300 | 12.5 | 128.00 | 1.370 | - | 1 | * | |

16.0 | 161.00 | 1.370 | - | 1 | * |

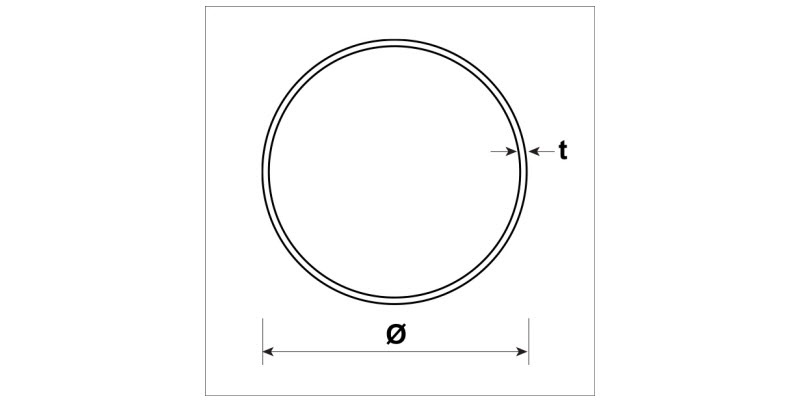

Circular Hollow Section - CHS

Cold-formed Circular Hollow Section (CHS) steel pipes are long, hollow tubes available in a variety of specifications and dimensions. These sections are versatile and can be used in many different applications including building construction, structural and mechanical. The main benefit of CHS is its strength. Steel pipes don’t crack under most impacts and can operate under high pressure. Under abnormal loads, CHS will bend, rather than break. Ferrocut’s Circular Hollow Sections are manufactured in accordance with the requirements of Australian Standard AS/NZS 1074:1991

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 1074:1991

SIZE MM | CLASS | OD (Ø) MM | NOM.THICK (T) MM | SURFACE AREA M2/M | NOM.LINEAR MASS BLACK KG/M | NOM.LINEAR MASS GALVANISED KG/M | QUANTITY PER PACK |

20 | M | 26.9 | 2.6 | 0.085 | 1.56 | 1.60 | 127 |

25 | XL | 33.7 | 2.0 | 0.106 | 1.56 | 1.62 | 91 |

L | 33.7 | 2.6 | 0.106 | 1.99 | 2.05 | 91 | |

M | 33.7 | 3.2 | 0.106 | 2.41 | 2.46 | 91 | |

H | 33.7 | 4.0 | 0.106 | 2.94 | 2.99 | 91 | |

32 | XL | 42.4 | 2.0 | 0.133 | 1.99 | 2.07 | 61 |

L | 42.4 | 2.6 | 0.133 | 2.55 | 2.63 | 61 | |

M | 42.4 | 3.2 | 0.133 | 3.10 | 3.17 | 61 | |

H | 42.4 | 4.0 | 0.133 | 3.80 | 3.86 | 61 | |

40 | XL | 48.3 | 2.3 | 0.152 | 2.61 | 2.70 | 61 |

L | 48.3 | 2.9 | 0.152 | 3.25 | 3.30 | 61 | |

M | 48.3 | 3.2 | 0.152 | 3.57 | 3.64 | 61 | |

H | 48.3 | 4.0 | 0.152 | 4.38 | 4.45 | 61 | |

XH | 48.3 | 5.4 | 0.152 | 5.71 | - | 61 | |

50 | XL | 60.3 | 2.3 | 0.189 | 3.29 | 3.40 | 37 |

L | 60.3 | 2.9 | 0.189 | 4.11 | 4.21 | 37 | |

M | 60.3 | 3.6 | 0.189 | 5.03 | 5.14 | 37 | |

H | 60.3 | 4.5 | 0.189 | 6.19 | 6.33 | 37 | |

XH | 60.3 | 5.4 | 0.189 | 7.31 | - | 37 | |

65 | XL | 76.1 | 2.3 | 0.239 | 4.19 | 4.32 | 37 |

L | 76.1 | 3.2 | 0.239 | 5.75 | 5.89 | 37 | |

M | 76.1 | 3.6 | 0.239 | 6.43 | 6.57 | 37 | |

H | 76.1 | 4.5 | 0.239 | 7.93 | 8.08 | 37 | |

80 | XL | 88.9 | 2.6 | 0.279 | 5.53 | 5.70 | 19 |

L | 88.9 | 3.2 | 0.279 | 6.76 | 6.93 | 19 | |

M | 88.9 | 4.0 | 0.279 | 8.37 | 8.54 | 19 | |

H | 88.9 | 5.0 | 0.279 | 10.3 | 10.6 | 19 | |

XH | 88.9 | 100 | 0.279 | 12.1 | - | 19 | |

90 | XL | 101.6 | 2.6 | 0.319 | 6.35 | - | 19 |

L | 101.6 | 3.2 | 0.319 | 7.77 | 7.95 | 19 | |

M | 101.6 | 4.0 | 0.319 | 9.63 | 9.81 | 19 | |

H | 101.6 | 5.0 | 0.319 | 11.9 | - | 19 | |

100 | XL | 114.3 | 3.2 | 0.359 | 8.77 | - | 19 |

L | 114.3 | 3.6 | 0.359 | 9.83 | 10.00 | 19 | |

M | 114.3 | 4.5 | 0.359 | 12.2 | 12.4 | 19 | |

H | 114.3 | 5.4 | 0.359 | 14.5 | 14.70 | 19 | |

125 | XL | 139.7 | 3.0 | 0.439 | 10.1 | - | 10 |

L | 139.7 | 3.5 | 0.439 | 11.8 | 12.00 | 10 | |

M | 139.7 | 5.0 | 0.439 | 16.6 | 16.90 | 10 | |

H | 139.7 | 5.4 | 0.439 | 17.9 | - | 10 | |

150 | XL | 165.1 | 3.0 | 0.519 | 12.0 | - | 10 |

L | 165.1 | 3.5 | 0.519 | 13.9 | 14.30 | 10 | |

M | 165.1 | 5.0 | 0.519 | 19.7 | 20.00 | 10 | |

H | 165.1 | 5.4 | 0.519 | 21.3 | - | 10 |

Firepipe

Firepipe is often made from carbon steel or iron and is used to carry water/liquid to fire safety/firefighting equipment. These pipes are designed to withstand rusting and corrosion, extreme temperatures and high pressure. Ferrocut’s Firepipe steel product is available in a range of wall thicknesses and diameters and is manufactured in accordance with the requirements of Australian Standard AS/NZS 1074:1991.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 1074:1991

NB MM | CLASS | OD (Ø) MM | NOM.THICK (T) MM | SURFACE AREA M2/M | NOM.LINEAR MASS KG/M | QUANTITY PER PACK | PE | PE | PE |

25 | M | 33.7 | 3.2 | 0.106 | 2.41 | 91 | * | * | * |

32 | M | 42.4 | 3.2 | 0.133 | 3.10 | 61 | * | * | * |

40 | M | 48.3 | 3.2 | 0.152 | 3.57 | 61 | * | * | * |

50 | M | 60.3 | 3.6 | 0.189 | 5.03 | 37 | * | * | * |

65 | M | 76.1 | 3.6 | 0.239 | 6.43 | 37 | * | ||

80 | M | 88.9 | 4.0 | 0.279 | 8.37 | 19 | * | ||

100 | M | 114.3 | 4.5 | 0.359 | 12.2 | 19 | * | ||

150 | M | 165.1 | 5.0 | 0.519 | 19.7 | 10 | * |

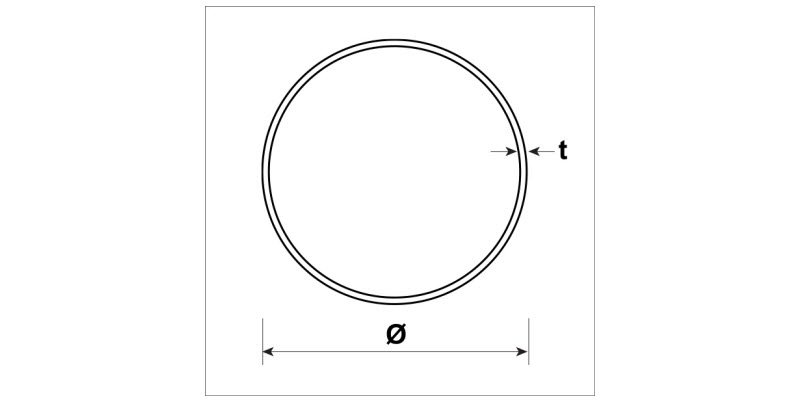

Large Structural Pipe

Ferrocut’s Large Structural Pipes are available in a variety of sizes, grades and wall thicknesses, and are typically available in 9m and 12m lengths. The Large Structural Steel Pipe range is well suited to a variety of applications including wind-resistant sign poles, stable caissons, irrigation works, structural piling and creek crossings, and they serve as bracings for jack and boring installations. The versatile large diameter pipes showcase good corrosion resistance and enhanced adhesion properties and are manufactured in accordance with the requirements of Australian Standard AS/NZS 1163:2009.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 1163:2009 in Grade C350

- Typically supplied in 9m & 12m lengths

NB MM | OD (Ø) MM | NOM.THICK (T) MM | SURFACE AREA M2/M | NOM.LINEAR MASS |

65 | 76.1 | 4.00 | 0.239 | 7.13 |

65 | 76.1 | 5.00 | 0.239 | 8.77 |

80 | 88.9 | 5.50 | 0.279 | 11.31 |

100 | 114.3 | 4.80 | 0.359 | 12.96 |

100 | 114.3 | 6.00 | 0.359 | 16.02 |

125 | 114.3 | 4.80 | 0.444 | 16.16 |

125 | 114.3 | 6.60 | 0.444 | 21.99 |

150 | 168.3 | 4.80 | 0.528 | 19.35 |

150 | 168.3 | 6.40 | 0.528 | 25.55 |

150 | 168.3 | 7.10 | 0.528 | 28.22 |

150 | 168.3 | 11.0 | 0.528 | 42.67 |

200 | 219.1 | 4.80 | 0.688 | 25.37 |

200 | 219.1 | 6.40 | 0.688 | 33.57 |

200 | 219.1 | 8.20 | 0.688 | 42.60 |

200 | 219.1 | 12.7 | 0.688 | 64.64 |

250 | 273.1 | 4.80 | 0.858 | 31.76 |

250 | 273.1 | 6.40 | 0.858 | 42.09 |

250 | 273.1 | 9.27 | 0.858 | 60.50 |

250 | 273.1 | 12.7 | 0.858 | 81.55 |

300 | 323.9 | 6.40 | 1.017 | 50.11 |

300 | 323.9 | 9.50 | 1.017 | 73.66 |

300 | 323.9 | 12.7 | 1.017 | 97.50 |

350 | 355.6 | 6.40 | 1.117 | 55.10 |

350 | 355.6 | 9.50 | 1.117 | 81.10 |

350 | 355.6 | 12.7 | 1.117 | 107.40 |

400 | 406.4 | 6.40 | 1.276 | 63.13 |

400 | 406.4 | 9.50 | 1.276 | 92.98 |

400 | 406.4 | 12.7 | 1.276 | 123.30 |

450 | 457.0 | 6.40 | 1.435 | 71.12 |

450 | 457.0 | 9.50 | 1.435 | 104.84 |

450 | 457.0 | 12.7 | 1.435 | 139.30 |

500 | 508.0 | 6.40 | 1.595 | 79.20 |

500 | 508.0 | 9.50 | 1.595 | 116.79 |

500 | 508.0 | 12.7 | 1.595 | 155.12 |

600 | 610.0 | 6.40 | 1.915 | 95.26 |

600 | 610.0 | 9.50 | 1.915 | 140.68 |

600 | 610.0 | 12.7 | 1.915 | 187.06 |

600 | 610.0 | 16.0 | 1.915 | 232.94 |

650 | 660.0 | 12.7 | 2.072 | 202.74 |

700 | 711.0 | 9.53 | 2.233 | 164.34 |

700 | 711.0 | 12.7 | 2.233 | 218.71 |

700 | 711.0 | 15.9 | 2.233 | 272.56 |

750 | 762.0 | 9.50 | 2.393 | 176.84 |

750 | 762.0 | 12.7 | 2.393 | 234.68 |

750 | 762.0 | 15.9 | 2.393 | 292.54 |

750 | 762.0 | 19.05 | 2.393 | 348.99 |

800 | 813.0 | 9.50 | 2.553 | 188.82 |

800 | 813.0 | 12.7 | 2.553 | 250.64 |

800 | 813.0 | 16.0 | 2.553 | 314.39 |

900 | 914.0 | 9.50 | 2.870 | 211.91 |

900 | 914.0 | 12.7 | 2.870 | 282.29 |

900 | 914.0 | 15.9 | 2.870 | 352.16 |

1050 | 1067.0 | 9.53 | 3.350 | 248.52 |

1050 | 1067.0 | 12.7 | 3.350 | 330.19 |

Need help with your structural tube and pipe order?

We’re here to answer your questions and customise your order to suit your project requirements. Contact us today to discuss your steel needs. See our other steel products.