Plasma cutting, laser cutting and oxy cutting are our specialist steel profiling capabilities. Whether you need critical flatness, minimum heat transfer or a tight tolerance, we have the machine and capability to deliver.

The Shape of Things to Come

Steel Profiling

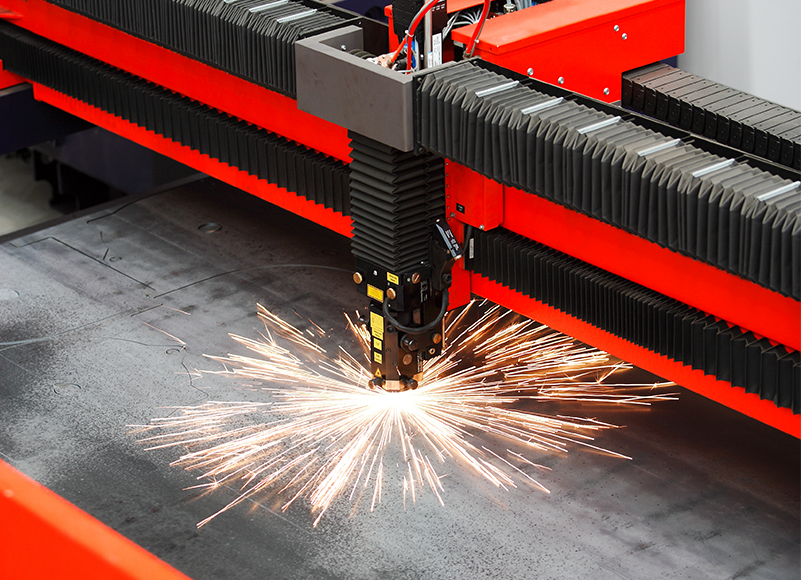

Plasma cutting

Working at ultra-high temperatures of over 2000 degrees Celsius, the plasma cutting system’s arc directs a stream of ionised gas to transfer energy and cut conductive metals, including mild steel, carbon steel, stainless steel, aluminium and other metals.

Our plasma cutting capability allows us to produce highly accurate shapes, including bevelled edges. Our four high-definition plasma cutting machines can cut long beds and extra-long plates of steel with ease and efficiency.

We can cut all steel plate products including mild steel, quench and tempered steel up to a maximum size of 3500 W x 22000 L. We have the capability to cut up to 80mm thick with tight tolerances.

Laser cutting

We have industry-leading laser cutting equipment, used by steel specialists who really know their craft.

Our technology allows us to cut extra-long lengths of steel beds with exact precision. We can laser cut all steel sheet products including mild steel grades 250 and 350. We can handle steel components of up to 2400 x 6500 bed size, cut up to 20mm thick and hold tolerances of -1mm or tighter.

Our expert team works with each of our clients to deliver laser cutting solutions tailored to the project requirements. We provide recommendations on the best cutting solution for your project.

Oxy cutting

At Ferrocut, we are backed by years of experience in delivering precision, large-scale and high-volume steel oxy cutting solutions. Oxy cutting is ideal for thicker materials.

Using oxygen and fuel gases, oxy cutting delivers precise cuts through thick steel plates with neat finishing. We have the capability to CNC cut all plate products including carbon and low alloy steels, mild steel and quenched and tempered steel types, up to a maximum size of 3500W x 22000L.

We use oxy cutting or multi-cutting techniques to cut steel up to 300mm thick, with 360 degree bevelling.

Not sure which cutting solution is best?

Trust us to deliver expert advice on the best solution for your project requirements. Our steel experts are backed by years of industry experience to deliver high-quality steel profiling for easy assembly.

Contact us today to talk to one of our friendly steel experts.

Case Studies - Our Clients’ Stories

Engineering company relies on Ferrocut as a bespoke engineering steel supplier

“Ferrocut takes initiative, which is priceless. Our team members always enjoy calling Ferrocut.”

A steel partnership between a major construction group and Ferrocut

“I would recommend Ferrocut because of their service, their quality, and because we know they operate out of a state-of-the-art facility.”

Ferrocut partners with one of SA’s heavy steel fabricators

“The Ferrocut team is willing to help when we are in a bind. They stand by any issues that they have and sort them out ASAP.”