Our complete range of merchant bar products is suitable for use in structural applications that involve welding, bending, punching and forming. Whether you need angle bars, round bars, square bars, flat bars or channels for your project, Ferrocut has what you need, available in a wide range of stock sizes.

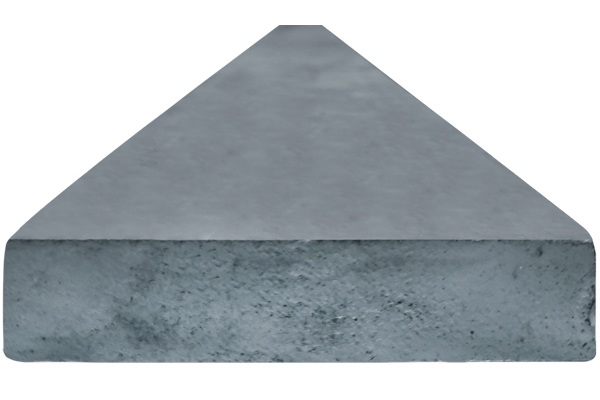

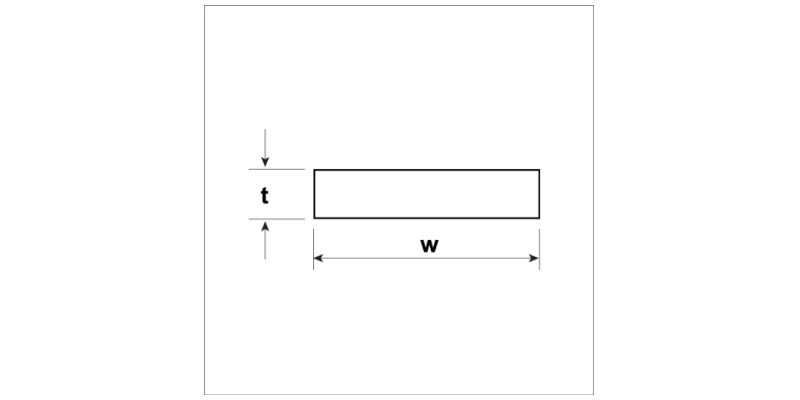

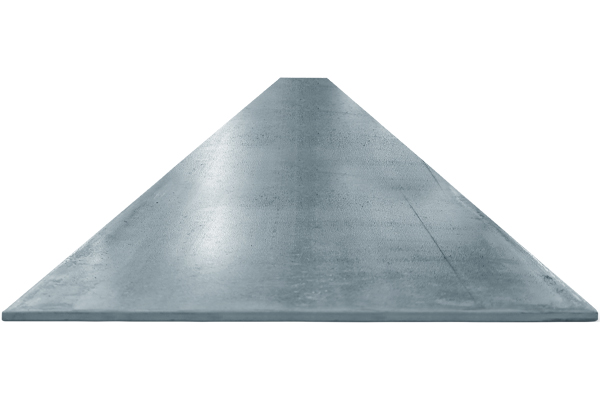

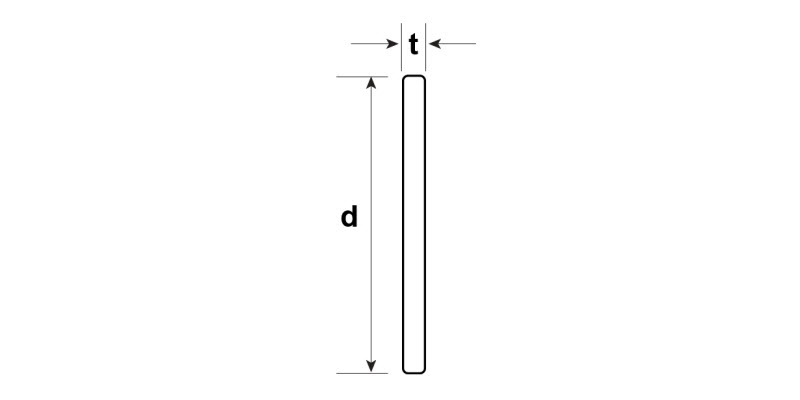

Square Edge Flats

Square Edge Flats are solid flat-surface steel sections with a rectangular cross-section area that can be cut, drilled and formed. Available in various grades and in a wide variety of sizes, Square Edge Flats are commonly used in engineering, residential and non-residential construction, manufacturing, transport, storage and mining infrastructure. Ferrocut’s Square Edge Flats are manufactured in Australia from 300PLUS steel and exceed the minimum requirements of AS/NZS 3679.1.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 3679.1 2016 in Grade 300

- Grade 350 & 350L0 available on request

- Non-standard lengths or cut to size on request

- 10x3mm flats supplied in 4m lengths

- 16×8 and above flats supplied in 6m lengths

- All lens/bundle are approx

- Denotes Rydal Flats

DESIGNATION | WEIGHT KG/M | SURFACE AREA | WIDTH (W) | THICKNESS (T) | METRES PER TONNE | APPROX LENS PER BUNDLE |

10x3* | 0.241 | 0.026 | 10 | 3 | 4149.4 | 964 = 1t |

13x3* | 0.313 | 0.032 | 13 | 3 | 3194.9 | 798 = 1t |

13x5* | 0.468 | 0.036 | 13 | 5 | 2136.8 | 478 = 1t |

13x6 | 0.628 | 0.038 | 13 | 6 | 1593.4 | 398 = 1t |

16x3* | 0.386 | 0.038 | 16 | 3 | 2590.7 | 647 = 1t |

16x5* | 0.643 | 0.042 | 16 | 5 | 1555.2 | 388 = 1t |

16x8* | 1.030 | 0.048 | 16 | 8 | 970.9 | 160 = 0.989t |

20x3 | 0.483 | 0.046 | 20 | 3 | 2070.4 | 346 = 1.002t |

20x5 | 0.805 | 0.050 | 20 | 5 | 1242.2 | 208 = 1.004t |

20x6 | 0.966 | 0.052 | 20 | 6 | 1035.2 | 173 = 1.002t |

20x10 | 1.609 | 0.060 | 20 | 10 | 621.5 | 208 = 2.008t |

25x3 | 0.604 | 0.058 | 25 | 3 | 1655.6 | 277 = 1.003t |

25x5 | 1.006 | 0.060 | 25 | 5 | 994.0 | 332 = 2.004t |

25x6 | 1.207 | 0.062 | 25 | 6 | 828.5 | 278 = 2.013t |

25x8 | 1.609 | 0.066 | 25 | 8 | 621.5 | 208 = 2.008t |

25x10 | 2.012 | 0.070 | 25 | 10 | 497.0 | 166 = 2.004t |

25x12 | 2.414 | 0.074 | 25 | 12 | 414.3 | 138 = 1.999t |

32x3 | 0.772 | 0.072 | 32 | 3 | 1295.3 | 219 - 1.015t |

32x5 | 1.287 | 0.074 | 32 | 5 | 777.0 | 265 = 2.047t |

32x6 | 1.545 | 0.076 | 32 | 6 | 647.2 | 215 = 1.993t |

32x8 | 2.060 | 0.080 | 32 | 8 | 485.4 | 162 = 2.002t |

32x10 | 2.575 | 0.084 | 32 | 10 | 388.3 | 129 = 1.993t |

32x12 | 3.090 | 0.088 | 32 | 12 | 323.6 | 108 = 2.002t |

40x3 | 0.966 | 0.088 | 40 | 3 | 1035.2 | 173 = 1.002t |

40x5 | 1.609 | 0.090 | 40 | 5 | 621.5 | 208 = 2.008t |

40x6 | 1.931 | 0.092 | 40 | 6 | 517.9 | 173 = 2.005t |

40x8 | 2.575 | 0.096 | 40 | 8 | 388.3 | 129 = 1.993t |

40x10 | 3.219 | 0.10 | 40 | 10 | 310.7 | 103 = 1.989t |

40x12 | 3.862 | 0.104 | 40 | 12 | 258.9 | 87 = 2.016t |

40x16 | 5.150 | 0.112 | 40 | 16 | 194.2 | 66 = 2.039t |

40x20 | 6.437 | 0.120 | 40 | 20 | 155.4 | 52 = 2.008t |

50x3 | 1.207 | 0.108 | 50 | 3 | 828.5 | 280 = 2.027t |

50x5 | 2.012 | 0.110 | 50 | 5 | 497.0 | 166 = 2.004t |

50x6 | 2.414 | 0.112 | 50 | 6 | 414.3 | 139 = 2.013t |

50x8 | 3.219 | 0.116 | 50 | 8 | 310.7 | 104 = 2.008t |

50x10 | 4.023 | 0.120 | 50 | 10 | 248.6 | 83 = 2.004t |

50x12 | 4.828 | 0.124 | 50 | 12 | 207.1 | 69 = 1.999t |

50x16 | 6.437 | 0.132 | 50 | 16 | 155.4 | 52 = 2.008t |

50x20 | 8.046 | 0.140 | 50 | 20 | 124.3 | 42 = 2.028t |

50x25 | 10.058 | 0.150 | 50 | 25 | 99.4 | 34 = 2.052t |

65x3 | 1.569 | 0.136 | 65 | 3 | 637.3 | 213 = 2.005t |

65x5 | 2.615 | 0.140 | 65 | 5 | 382.4 | 127 = 1.993t |

65x6 | 3.138 | 0.142 | 65 | 5 | 318.7 | 107 = 2.015t |

65x8 | 4.184 | 0.146 | 65 | 8 | 239.0 | 80 = 2.008t |

65x10 | 5.230 | 0.150 | 65 | 10 | 191.2 | 65 = 2.040t |

65x12 | 6.276 | 0.154 | 65 | 12 | 159.3 | 53 = 1.996t |

65x16 | 8.368 | 0.162 | 65 | 16 | 119.5 | 41 = 2.059t |

65x20 | 10.460 | 0.170 | 65 | 20 | 95.6 | 35 = 2.197t |

75x5 | 3.017 | 0.160 | 75 | 5 | 331.5 | 110 = 1.991t |

75x6 | 3.621 | 0.162 | 75 | 6 | 276.2 | 92 = 1.999t |

75x8 | 4.828 | 0.166 | 75 | 8 | 207.1 | 71 = 2.057t |

75x10 | 6.035 | 0.170 | 75 | 10 | 165.7 | 55 = 1.991t |

75x12 | 7.242 | 0.174 | 75 | 12 | 138.1 | 46 = 1.999t |

75x16 | 9.656 | 0.182 | 75 | 16 | 103.6 | 34 = 1.970t |

75x20 | 12.069 | 0.190 | 75 | 20 | 82.9 | 28 = 2.028t |

75x25 | 15.087 | 0.200 | 75 | 25 | 66.3 | 23 = 2.029t |

90x6 | 4.345 | 0.192 | 90 | 6 | 230.1 | 78 = 2.033t |

90x8 | 5.793 | 0.196 | 90 | 8 | 172.6 | 59 = 2.051t |

90x10 | 7.242 | 0.200 | 90 | 10 | 138.1 | 46 = 1.999t |

90x12 | 8.690 | 0.204 | 90 | 12 | 115.1 | 38 = 1.981t |

100x5 | 4.023 | 0.210 | 100 | 5 | 248.6 | 85 = 2.052t |

100x6 | 4.828 | 0.212 | 100 | 6 | 207.1 | 71 = 2.057t |

100x8 | 6.437 | 0.216 | 100 | 8 | 155.4 | 52 = 2.008t |

100x10 | 8.046 | 0.220 | 100 | 10 | 124.3 | 43 = 2.076t |

100x12 | 9.656 | 0.224 | 100 | 12 | 103.6 | 36 = 2.086t |

100x16 | 12.874 | 0.232 | 100 | 16 | 77.7 | 26 = 2.008t |

100x20 | 16.093 | 0.240 | 100 | 20 | 62.1 | 22 = 2.124t |

100x25 | 20.116 | 0.250 | 100 | 25 | 49.7 | 17 = 2.052t |

110x6 | 5.180 | 0.232 | 110 | 6 | 193.1 | 64 = 2.034t |

110x8 | 7.081 | 0.236 | 110 | 8 | 141.2 | 48 = 2.039t |

110x10 | 8.851 | 0.240 | 110 | 10 | 113.0 | 39 = 2.071t |

110x12 | 10.621 | 0.244 | 110 | 12 | 94.2 | 34 = 2.167t |

130x5 | 5.230 | 0.270 | 130 | 5 | 191.2 | 65 = 2.040t |

130x6 | 6.276 | 0.272 | 130 | 6 | 159.3 | 55 = 2.071t |

130x8 | 8.368 | 0.276 | 130 | 8 | 119.5 | 41 = 2.059t |

130x10 | 10.460 | 0.280 | 130 | 10 | 95.6 | 33 = 2.071t |

130x12 | 12.552 | 0.284 | 130 | 12 | 79.7 | 28 = 2.109t |

130x16 | 16.736 | 0.292 | 130 | 16 | 59.8 | 20 = 2.008t |

130x20 | 20.920 | 0.300 | 130 | 20 | 47.8 | 16 = 2.008t |

130x25 | 26.150 | 0.310 | 130 | 25 | 38.2 | 13 = 2.040t |

150x5 | 6.035 | 0.310 | 150 | 5 | 165.7 | 56 = 2.028t |

150x6 | 7.242 | 0.312 | 150 | 6 | 138.1 | 46 = 1.999t |

150x8 | 9.656 | 0.316 | 150 | 8 | 103.6 | 36 = 2.086t |

150x10 | 12.069 | 0.320 | 150 | 10 | 82.9 | 29 = 2.100t |

150x12 | 14.483 | 0.324 | 150 | 12 | 69.0 | 23 = 1.999t |

150x16 | 19.311 | 0.332 | 150 | 16 | 51.8 | 16 = 2.202t |

150x20 | 24.139 | 0.340 | 150 | 20 | 41.4 | 14 = 2.028t |

150x25 | 30.173 | 0.350 | 150 | 25 | 33.1 | 11 = 1.991t |

150x50 | 60.346 | 0.400 | 150 | 50 | 16.6 | 5 = 1.810t |

180x6 | 8.690 | 0.372 | 180 | 6 | 115.1 | 40 = 2.086t |

180x10 | 14.483 | 0.380 | 180 | 10 | 69.0 | 24 = 2.086t |

180x12 | 17.380 | 0.384 | 180 | 12 | 57.5 | 20 = 2.086t |

180x16 | 23.173 | 0.392 | 180 | 16 | 43.2 | 11 = 1.529t |

180x20 | 28.967 | 0.400 | 180 | 20 | 34.5 | 12 = 2.086t |

180x25 | 36.208 | 0.450 | 180 | 25 | 27.6 | 9 = 1.955t |

200x6 | 9.656 | 0.412 | 200 | 6 | 103.6 | 35 = 2.086t |

200x8 | 12.874 | 0.416 | 200 | 8 | 77.7 | 26 = 2.008t |

200x10 | 16.093 | 0.420 | 200 | 10 | 62.1 | 21 = 2.086t |

200x12 | 19.311 | 0.424 | 200 | 12 | 51.8 | 13=2.008t |

200x16 | 25.748 | 0.432 | 200 | 16 | 38.8 | 14=2.163t |

200x20 | 32.185 | 0.440 | 200 | 20 | 31.1 | 11=2.124t |

200x25 | 40.231 | 0.450 | 200 | 25 | 24.9 | 8=1.931t |

250x6 | 12.069 | 0.512 | 250 | 6 | 82.9 | 28=2.028t |

250x8 | 16.093 | 0.516 | 250 | 8 | 62.1 | 23=2.221t |

250x10 | 20.116 | 0.520 | 250 | 10 | 49.7 | 18=2.172t |

250x12 | 24.139 | 0.524 | 250 | 12 | 41.4 | 16=2.317t |

250x16 | 32.185 | 0.528 | 250 | 16 | 31.1 | 11=2.124t |

250x20 | 40.231 | 0.532 | 250 | 20 | 24.9 | 8=1.931t |

250x25 | 50.289 | 0.536 | 250 | 25 | 19.9 | 7=2.112t |

300x6 | 14.483 | 0.612 | 300 | 6 | 69.0 | 24 = 2.086t |

300x8 | 19.311 | 0.616 | 300 | 8 | 51.8 | 19=2.202t |

300x10 | 24.139 | 0.620 | 300 | 10 | 41.4 | 16=2.317t |

300x12 | 28.967 | 0.624 | 300 | 12 | 34.5 | 12=2.086t |

300x16 | 38.622 | 0.628 | 300 | 16 | 25.9 | 10=2.317t |

300x20 | 48.278 | 0.632 | 300 | 20 | 20.7 | 8=2.317t |

300x25 | 60.347 | 0.636 | 300 | 25 | 16.6 | 7=2.535t |

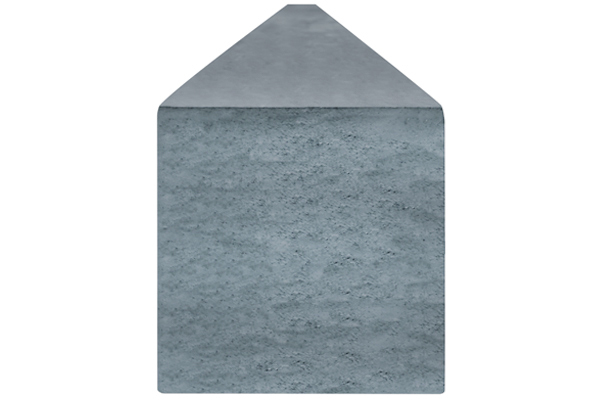

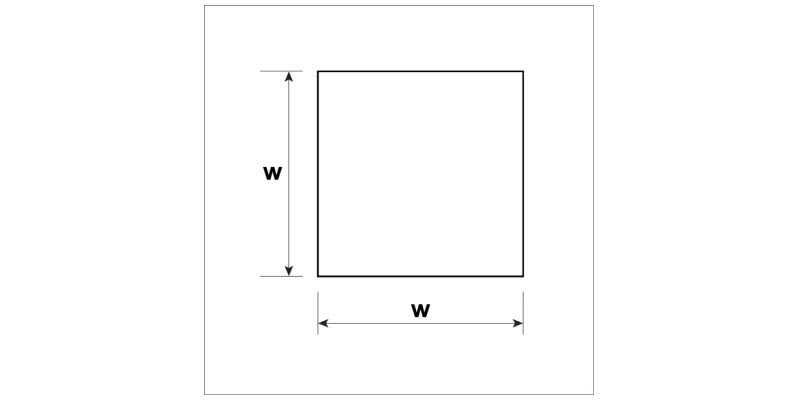

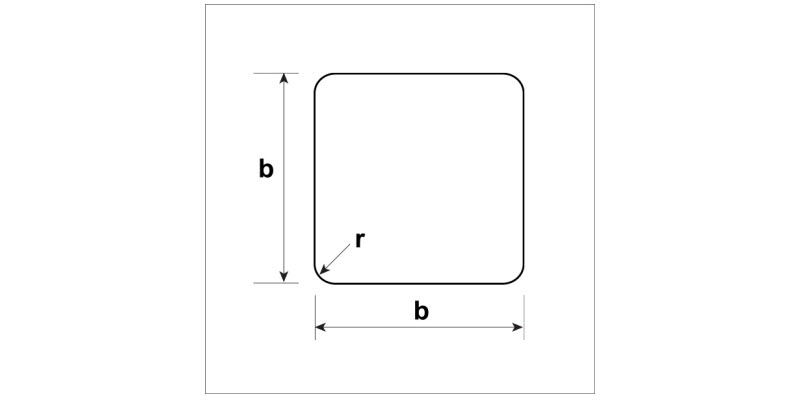

Square Mild Steel

Square Mild Steel bars are durable, solid steel bars, available in different sizes, making them very versatile. Square Mild Steel bars are very easy to weld and are strong and rigid, being able to withstand a range of weather conditions. They are often used for reinforcements, fences, gates, security doors, windows and door trims as well as other ornate architectural and balustrade applications. Manufactured in Australia from Grade 300PLUS Steel, Ferrocut’s Square Mild Steel bars meet the relevant Australian and New Zealand standards of AS/NZS 3679.1:2016.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 3679.1 2016 in Grade 300

- Grade 350 & 350L0 available on request

- Non-standard lengths or cut to size on request

- Supplied in 6m lengths

- Corner radius on Squares is approximately 1.0mm

DESIGNATION | WEIGHT KG/M | SURFACE AREA M2/M | WIDTH (W) MM | METRES PER TONNE | APPROX LENS PER BUNDLE |

10x10 | 0.805 | 0.004 | 10 | 1242.2 | 415 = 2.004t |

12x12 | 1.159 | 0.048 | 12 | 862.8 | 291 = 2.023t |

16x16 | 2.060 | 0.064 | 16 | 485.4 | 163 = 2.015t |

20x20 | 3.219 | 0.080 | 20 | 310.7 | 104 = 2.008t |

25x25 | 5.029 | 0.100 | 25 | 198.8 | 66 = 1.991t |

40x40 | 12.874 | 0.160 | 40 | 77.7 | 26 = 1.965t |

Billets

Steel Billets are hot rolled square bars produced by hot rolling continuous casting billets. Billets can be transformed into a variety of shapes and sizes after the processing stage and are often rectangular, circular or square shaped. Steel Billets are used in expulsion, fashioning, rolling and other metal-processing operations such as a raw material or feedstock. Ferrocut’s Billets are manufactured in accordance with the requirements of Australian Standard AS 1442/1022-1045.

- Manufactured in accordance with the requirements of Australian Standard AS 1442/1022-1045

- Larger square sections may need to be cut from a thick plate

DESIGNATION | WEIGHT KG/M | SURFACE AREA M2/M | SIZE (B) | METRES PER TONNE | CORNER RADIUS (R) |

45x45 | 16.294 | 0.18 | 45 | 61.4 | 5.5 |

50x50 | 20.115 | 0.2 | 50 | 49.7 | 6.5 |

63x63 | 31.936 | 0.26 | 63 | 31.3 | 8.0 |

75x75 | 45.260 | 0.3 | 75 | 22.1 | 9.5 |

Round Mild Steel

Round Mild Steel bars are characterised by their circular cross section. Round Mild Steel has a smaller carbon quantity than other types of steel making it easier to cut, form, drill and machine. Round Mild Steel bars are often used as reinforcement and can be used in a wide variety of industrial, commercial and residential applications. Manufactured in Australia from 300PLUS steel, Ferrocut’s Round Mild Steel bars meet the relevant Australian and New Zealand standards of AS/NZS 3679.1 – 300.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 3679.1 2016 in Grade 300

- Grade 350 & 350L0 available on request

- Typically supplied in 6m lengths

- Longer lengths available on request

DIAMETER (Ø) | WEIGHT KG/M | SURFACE AREA M2/M | METRES PER TONNE | APPROX LENGTH PER BUNDLE |

6 | 0.233 | 0.020 | 4291.8 | 664 = 1.000t |

8 | 0.394 | 0.025 | 2538.1 | 530 = 2.009t |

10 | 0.632 | 0.031 | 1582.3 | 530 = 2.009t |

12 | 0.910 | 0.039 | 1098.9 | 367 = 2.004t |

14 | 1.239 | 0.044 | 807.1 | 271 = 2.014t |

16 | 1.618 | 0.050 | 618.0 | 206 = 1.999t |

18 | 2.047 | 0.057 | 488.5 | 168 = 2.064t |

20 | 2.528 | 0.063 | 395.6 | 132 = 2.002t |

22 | 3.059 | 0.069 | 326.9 | 110 = 2.019t |

24 | 3.640 | 0.075 | 274.7 | 93 = 2.031t |

27 | 4.607 | 0.085 | 217.1 | 73 = 2.018t |

30 | 5.687 | 0.094 | 175.8 | 60 = 2.047t |

33 | 6.882 | 0.104 | 145.3 | 50 = 2.064t |

36 | 8.190 | 0.113 | 122.1 | 42 = 2.064t |

39 | 9.611 | 0.123 | 104.0 | 36 = 2.076t |

42 | 11.147 | 0.132 | 89.7 | 30 = 2.006t |

45 | 12.796 | 0.141 | 78.1 | 26 = 1.996t |

48 | 14.559 | 0.151 | 68.7 | 23 = 2.009t |

50 | 15.798 | 0.157 | 63.3 | 22 = 2.085t |

56 | 19.817 | 0.176 | 50.5 | 17 = 2.021t |

60 | 22.749 | 0.188 | 44.0 | 15 = 2.047t |

65 | 26.698 | 0.204 | 37.5 | 14 = 2.243t |

75 | 35.545 | 0.26 | 28.1 | 10 = 2.133t |

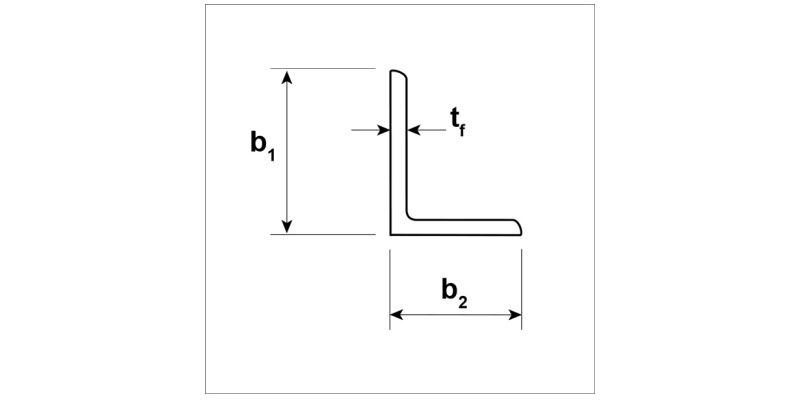

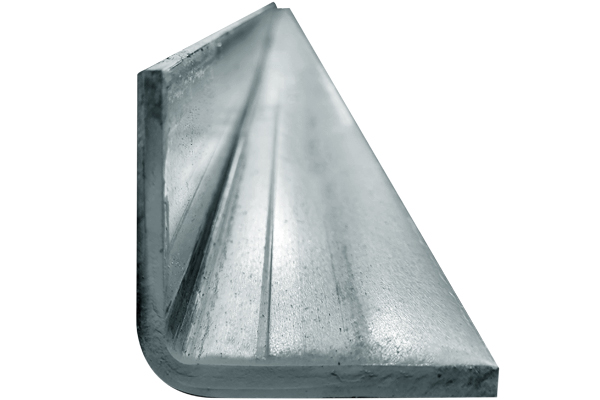

Equal Angles

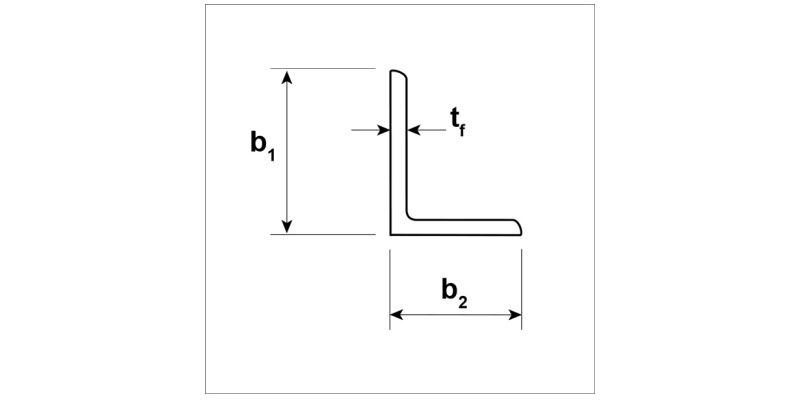

Steel Angles are the most basic type of roll-formed steel and are formed by bending a single angle in a piece of steel, creating a ‘L’ shaped product. Equal Angles have two axes of the same length (equal) that create a 90-degree angle. Equal Angles are multi-purposed and are often used for reinforcement, framing, trims and brackets. They can be cut to any size and can be made in a range of strengths and thicknesses. The larger the steel angle, the more weight and stress it can bear. Equal Angles are manufactured in accordance with AS/NZS 3679.1.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 3679.1 2016 in Grade 300

- Grade 350 & 350L0 available on request

- Non-standard lengths or cut to size on request

DESIGNATION | WEIGHT KG/M | SURFACE AREA M2/M | SIDE A (B1) | SIDE B (B1) | THICKNESS OF FLANGE (TF) |

100x100x12 | 17.700 | 0.392 | 100 | 100 | 12.0 |

100x100x10 | 14.200 | 0.392 | 100 | 100 | 9.5 |

100x100x8 | 11.800 | 0.392 | 100 | 100 | 7.8 |

100x100x6 | 9.160 | 0.392 | 100 | 100 | 6.0 |

90x90x10 | 12.700 | 0.352 | 90 | 90 | 9.5 |

90x90x8 | 10.600 | 0.352 | 90 | 90 | 7.8 |

90x90x6 | 8.220 | 0.352 | 90 | 90 | 6.0 |

75x75x10 | 10.500 | 0.292 | 75 | 75 | 9.5 |

75x75x8 | 8.730 | 0.292 | 75 | 75 | 7.8 |

75x75x6 | 6.810 | 0.292 | 75 | 75 | 6.0 |

75x75x5 | 5.270 | 0.292 | 75 | 75 | 4.6 |

65x65x10 | 9.020 | 0.255 | 65 | 65 | 9.5 |

65x65x8 | 7.510 | 0.255 | 65 | 65 | 7.8 |

65x65x6 | 5.870 | 0.255 | 65 | 65 | 6.0 |

65x65x5 | 4.560 | 0.255 | 65 | 65 | 4.6 |

55x55x5 | 3.840 | 0.215 | 55 | 55 | 4.6 |

50x50x8 | 5.680 | 0.195 | 50 | 50 | 7.8 |

50x50x6 | 4.460 | 0.195 | 50 | 50 | 6.0 |

50x50x5 | 3.480 | 0.195 | 50 | 50 | 4.6 |

50x50x3 | 2.310 | 0.195 | 50 | 50 | 3.0 |

45x45x6 | 3.970 | 0.175 | 45 | 45 | 6.0 |

45x45x5 | 3.100 | 0.175 | 45 | 45 | 4.6 |

45x45x3 | 2.060 | 0.175 | 75 | 22.1 | 3.0 |

40x40x6 | 3.500 | 0.155 | 40 | 40 | 6.0 |

40x40x5 | 2.730 | 0.155 | 40 | 40 | 4.6 |

40x40x3 | 1.830 | 0.155 | 40 | 40 | 3.0 |

30x30x6 | 2.560 | 0.115 | 30 | 30 | 6.0 |

30x30x5 | 2.010 | 0.115 | 30 | 30 | 4.6 |

30x30x3 | 1.350 | 0.115 | 30 | 30 | 3.0 |

25x25x6 | 2.080 | 0.095 | 25 | 25 | 6.0 |

25x25x5 | 1.650 | 0.095 | 25 | 25 | 4.6 |

25x25x3 | 1.120 | 0.095 | 25 | 25 | 3.0 |

Unequal Angles

Where the Equal Angle has two axes of the same length, Unequal Angles have two axes of different lengths (unequal) that create a 90-degree angle. The cross section has the same shape as an upper case ‘L’. Unequal Angles are often used in bridge building, reinforcements, framing and brackets and can be made in a range of thicknesses and strengths and can be cut to any size. Unequal Angles are manufactured in accordance with AS/NZS 3679.1.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 3679.1 2016 in Grade 300

- Grade 350 & 350L0 available on request

- Non-standard lengths or cut to size on request

DESIGNATION | WEIGHT KG/M | SURFACE AREA M2/M | SIDE A (B1) | SIDE B (B1) | THICKNESS OF FLANGE (TF) |

100x75x10 | 12.40 | 0.342 | 100 | 75 | 9.5 |

100x75x6 | 10.30 | 0.342 | 100 | 75 | 7.8 |

100x75x5 | 7.98 | 0.342 | 100 | 75 | 6.0 |

75x50x8 | 7.23 | 0.242 | 75 | 50 | 7.8 |

75x50x6 | 5.66 | 0.242 | 75 | 50 | 6.0 |

75x50x5 | 4.40 | 0.242 | 75 | 50 | 4.6 |

65x50x8 | 6.59 | 0.225 | 65 | 50 | 7.8 |

65x50x6 | 5.16 | 0.225 | 65 | 50 | 6.0 |

65x50x5 | 4.02 | 0.225 | 65 | 50 | 4.6 |

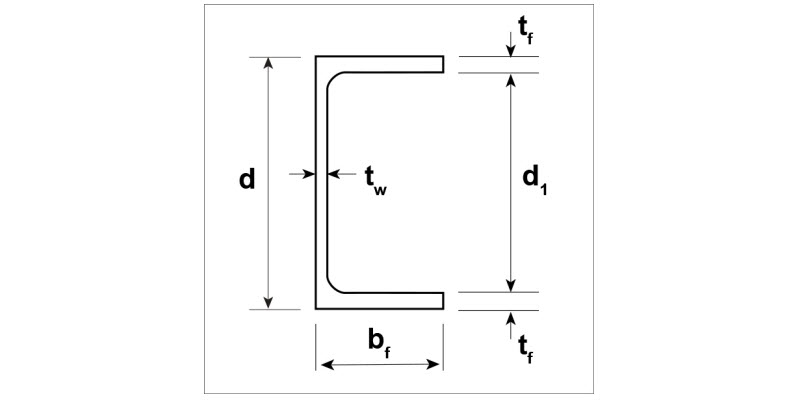

Parallel Flange Channels

Parallel Flange Channels (PFCs) are hot-rolled carbon steel channels sometimes referred to as ‘C sections’ or ‘C channel beams’ due to their shape. Constructed using a vertical web and top and bottom horizontal flanges with inside radius corners, the shape provides superior structural support, making Parallel Flange Channels an ideal product for frames and braces used for machinery, enclosures, vehicles, truss support beams, floor beams and portal frames. PFCs are available in a wide range of sizes and thicknesses.

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 3679.1 2016 in Grade 300

- Grade 350 & 350L0 available on request

- Non-standard lengths or cut to size on request

DESIGNATION | WEIGHT KG/M | SURFACE AREA M2/M | DEPTH OF SECTION (D) MM | WIDTH OF FLANGE (BF) MM | THICKNESS OF FLANGE (TF) | WEB THICKNESS (TW) MM | DEPTH BETWEEN FLANGES (D1) |

125PFC | 11.900 | 0.494 | 125 | 65 | 7.5 | 4.7 | 110 |

100PFC | 8.330 | 0.385 | 100 | 50 | 6.7 | 4.2 | 87 |

75PFC | 5.920 | 0.296 | 75 | 40 | 6.1 | 3.8 | 63 |

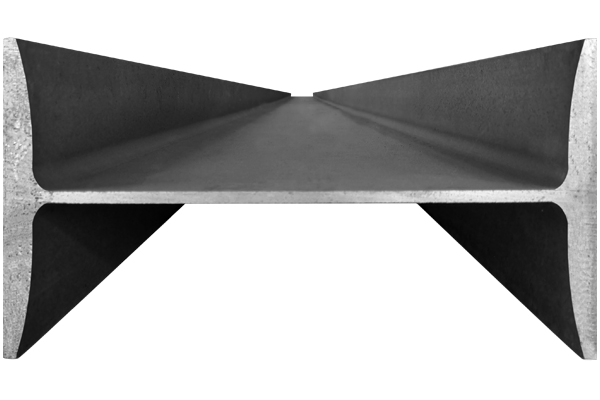

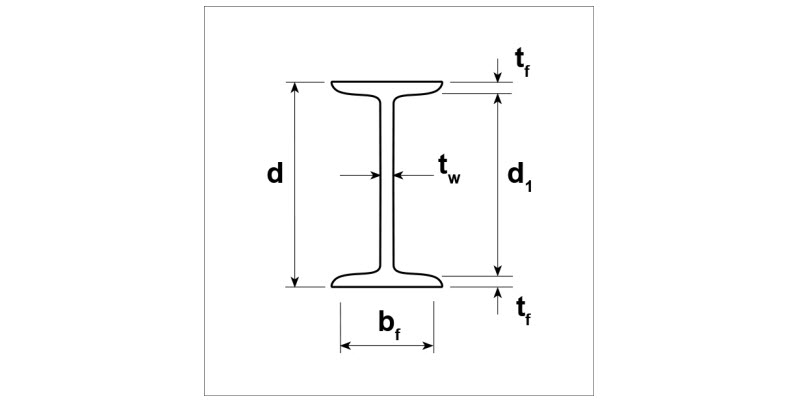

Tapered Flange Beams

Tapered Flange Beams are similar to the “𝚰” shape of Universal Beams, however they have tapered flanges – the two horizontal sections (flanges) taper, normally to a 98-degree angle from the web. Tapered Flange Beams are strong, as the flanges provide resistance to bending and are used regularly for support in residential and commercial construction projects as well as in industrial applications where maximal strength is paramount. Ferrocut stocks a range of Tapered Flange Beams in a variety of sizes and lengths, which are manufactured in Australia from 300PLUS steel and exceed the minimum requirements of AS/NZS 3679.1

- Manufactured in accordance with the requirements of Australian Standard AS/NZS 3679.1 2016 in Grade 300

- Grade 350 & 350L0 available on request

- Non-standard lengths or cut to size on request

DESIGNATION | WEIGHT KG/M | SURFACE AREA M2/M | DEPTH OF SECTION (D) MM | WIDTH OF FLANGE (BF) MM | THICKNESS OF FLANGE (TF) | WEB THICKNESS (TW) MM | DEPTH BETWEEN FLANGES (D1) |

125 TFB | 13.1 | 0.470 | 125 | 65 | 8.5 | 5.0 | 108 |

100 TFB | 7.2 | 0.349 | 100 | 45 | 6.0 | 4.0 | 88 |

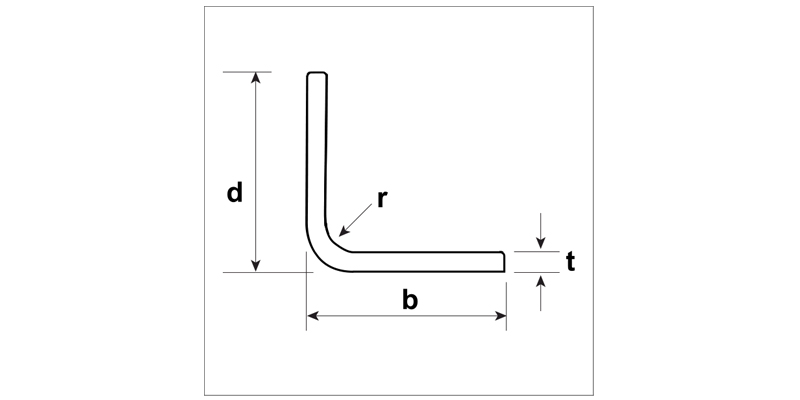

DuraGal® Angles

DuraGal® Angles are rollformed from high strength grade steel and protected with a highly corrosion resistant zinc coating that improves the bars’ resistance to rust, helps prevent cracking at the edges and works as a good base for powder coating or paint. Known for their superior strength, DuraGal® Angles come in various standard lengths and are commonly used in framing and structural applications that require a rust resistant product.

- Radius ‘r’ is a minimum 3.5mm.

- A minimum of 100g/m2 coating of zinc is applied by in-line galvanising to a mechanically (shot blasted) and chemically cleaned bright metal (AS 1627.4 Class 3.0) surface. A clear polymer barrier coating protects the galvanising prior to fabrication.

- DuraGal® is readily welded. Its thin, evenly applied in-line galvanised coating ensures minimal welding fumes. No need to preheat, change consumables or welding settings.

- Some items may require a 3 pack minimum order quantity.

DESIGNATION | WEIGHT KG/M | SURFACE AREA M2/M | DEPTH (D) | WIDTH (B) MM | THICKNESS (T) | LENGTH M | TOTAL QTY/PK |

25x25x2.5 | 0.894 | 0.095 | 25 | 25 | 2.5 | 6 | 80 |

30x30x2.5 | 1.093 | 0.117 | 30 | 30 | 2.5 | 6 | 80 |

40x40x2.5 | 1.490 | 0.157 | 40 | 40 | 2.5 | 6 | 60 |

40x40x4.0 | 2.310 | 0.155 | 40 | 40 | 4.0 | 7.8 | 39 |

45x45x2.5 | 1.689 | 0.175 | 45 | 45 | 2.5 | 6 | 54 |

50x50x2.5 | 1.888 | 0.197 | 50 | 50 | 2.5 | 6 | 27 |

50x50x2.5 | 1.888 | 0.197 | 50 | 50 | 2.5 | 9 | 33 |

50x50.4.0 | 2.943 | 0.195 | 50 | 50 | 4.0 | 6 | 27 |

50x50.4.0 | 2.943 | 0.195 | 50 | 50 | 4.0 | 9 | 27 |

50x50x5.0 | 3.594 | 0.195 | 50 | 50 | 5.0 | 6 | 24 |

50x50x5.0 | 3.594 | 0.195 | 50 | 50 | 5.0 | 9 | 24 |

50x50x5.0 | 3.594 | 0.195 | 50 | 50 | 5.0 | 12 | 24 |

50x50x6.0 | 4.210 | 0.195 | 50 | 50 | 6.0 | 9 | 21 |

65x65x4.0 | 3.892 | 0.255 | 65 | 65 | 4.0 | 9 | 22 |

65x65x5.0 | 4.779 | 0.255 | 65 | 65 | 5.0 | 9 | 22 |

75x75x4.0 | 4.525 | 0.295 | 75 | 75 | 4.0 | 9 | 22 |

75x75x5.0 | 5.569 | 0.293 | 75 | 75 | 4.0 | 9 | 22 |

75x75x6.0 | 6.664 | 0.292 | 75 | 75 | 6.0 | 9 | 18 |

100x100x6.0 | 9.078 | 0.392 | 100 | 100 | 6.0 | 12 | 16 |

125x75x6.0 | 9.078 | 0.392 | 125 | 75 | 6.0 | 12 | 16 |

150x100x6.0 | 11.492 | 0.500 | 150 | 100 | 6.0 | 12 | 16 |

DuraGal® Flats

DuraGal® Flats are made from galvanised steel and provide superior strength and corrosion protection in the harshest of environments. DuraGal® Flat bars have a zinc coating applied to them, which helps stop the bar from rusting, cracking at the edges and works as a good base for powder coating or paint. DuraGal® Flats come in various standard lengths and are commonly used in residential construction, non-residential construction and general applications.

- A minimum of 100g/m2 coating of zinc is applied by in-line galvanising to a mechanically (shot blasted) and chemically cleaned bright metal (AS 1627.4 Class 3.0) surface. A clear polymer barrier coating protects the galvanising prior to fabrication.

- DuraGal® is readily welded. Its thin evenly applied in-line galvanised coating ensures minimal welding fumes. No need to preheat, change consumables or welding settings.

- Some items may require a 3 pack minimum order quantity.

DESIGNATION | WEIGHT KG/M | SURFACE AREA M2/M | DEPTH (D) MM | THICKNESS (T) MM | LENGTH M | TOTAL QTY/PK |

50x4.0 | 1.582 | 0.108 | 50 | 4.0 | 6 | 75 |

50x5.0 | 1.975 | 0.110 | 50 | 5.0 | 6 | 45 |

65x5.0 | 2.567 | 0.140 | 65 | 5.0 | 6 | 36 |

75x4.0 | 2.373 | 0.158 | 75 | 4.0 | 6 | 38 |

75x5.0 | 2.962 | 0.160 | 75 | 4.0 | 6 | 32 |

100x4.0 | 3.165 | 0.208 | 100 | 4.0 | 6 | 28 |

100x5.0 | 3.950 | 0.210 | 100 | 5.0 | 6 | 28 |

100x6.0 | 4.829 | 0.212 | 100 | 6.0 | 6 | 26 |

130x5.0 | 5.134 | 0.270 | 130 | 5.0 | 6 | 28 |

150x5.0 | 5.924 | 0.310 | 150 | 5.0 | 6 | 28 |

150x6.0 | 7.243 | 0.312 | 150 | 6.0 | 6 | 24 |

200x6.0 | 9.657 | 0.512 | 250 | 6.0 | 6 | 28 |

250x5.0 | 9.874 | 0.510 | 250 | 5.0 | 6 | 23 |

DuraGal® Channels

DuraGal® Channels are rollformed from high strength grade steel and have the entire surface covered by a zinc layer that offers a long-term protective coating, better corrosion resistance, higher tensile strength and durability. DuraGal® Channels provide superior structural support, making them ideal for frames and braces used for machinery, enclosures, vehicles, building and structural support applications. DuraGal® Channels are available in an extensive range of thicknesses and sizes.

- Radius ‘r’ is a minimum 3.5mm.

- A minimum of 100g/m2 coating of zinc is applied by in-line galvanising to a mechanically (shot blasted) and chemically cleaned bright metal (AS 1627.4 Class 3.0) surface. A clear polymer barrier coating protects the galvanising prior to fabrication.

- DuraGal® is readily welded. Its thin evenly applied in-line galvanised coating ensures minimal welding fumes. No need to preheat, change consumables or welding settings.

- Some items may require a 3 pack minimum order quantity.

DESIGNATION | WEIGHT KG/M | SURFACE AREA M2/M | DEPTH (D) MM | WIDTH (B) MM | THICKNESS (T) | LENGTH M | TOTAL QTY/PK |

75x40x4.0 | 4.430 | 0.299 | 75 | 40 | 4.0 | 9 | 18 |

100x50x4.0 | 5.584 | 0.382 | 100 | 50 | 4.0 | 9 | 18 |

125x65x4.0 | 7.595 | 0.481 | 125 | 65 | 4.0 | 9 | 18 |

150x75x5.0 | 11.177 | 0.580 | 150 | 75 | 5.0 | 12 | 12 |

180X75X5.0 | 12.362 | 0.640 | 180 | 75 | 5.0 | 12 | 12 |

200x75x5.0 | 13.152 | 0.669 | 200 | 75 | 5.0 | 12 | 12 |

200x75x6.0 | 15.742 | 0.688 | 200 | 75 | 6.0 | 12 | 12 |

230x75x6.0 | 17.198 | 0.729 | 230 | 75 | 6.0 | 12 | 12 |

250x90x6.0 | 19.605 | 0.758 | 25 | 90 | 6.0 | 12 | 8 |

300X90X6.0 | 22.019 | 0.847 | 300 | 90 | 6.0 | 12 | 6 |

Need help with your merchant bar order?

We’re here to answer your questions and customise your order to suit your project requirements. Contact us today to discuss your steel needs. See our wide range of steel products.